Engineering and Product Development

-

Extensive design assistance and manufacturing process expertise

-

Your one-stop source from design concepts to delivery

-

Serving a wide range of industries and applications

Overview

CEI has more than 40 years of experience with developing and manufacturing complex components for uses ranging from consumer to mission critical. We understand that the development process must focus on the component’s required functional specifications, but also achieve successful and efficient manufacturability. Our development and prototyping expertise, in combination with diverse metal fabrication capabilities like tool and die making, metal stamping, machining, and wire EDM, allows us to design and execute the optimal manufacturing process for your program.

Capabilities

Our experienced technical staff will assist you in developing your components as required. We will start by gathering an understanding of your specific needs, your current design/manufacturing challenges (if any), and any other relevant considerations. We will leverage our design for manufacturing (DFM) experience to ensure that technical features are manufacturable, repeatable, and cost effective. This is especially important when custom tooling is required, and consistent volume production is the desired result.

CEI has a dedicated department to design and build tooling, fixtures, progressive stamping dies, compound stamping dies, in-process inspection gages, machining fixtures and more. Our skilled engineers use workstations that run SolidWorks and other programs to assist with design, engineering, and modelling.

Remember, CEI routinely manages the entire process for our OEM customers, from design assistance to delivery. We align all of our practices, policies, and production with the principles of Lean Manufacturing and Six Sigma. This adds up to quality products that are efficiently and consistently manufactured.

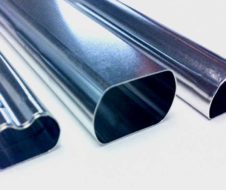

Materials – We work in many materials including stainless steel, cold rolled steel, aluminum, aerospace alloys, titanium, brass, tubing and more. Our engineers can assist with material selection as needed.

Industries and Applications

We have experience in designing, components used in subassemblies, systems, and equipment for a wide range of industries. This includes medical, automotive, aerospace, defense, industrial, consumer, electronics and more. Applications include, but are not limited to: surgical instruments, medical devices, jet engines, steering systems, valve housings, sensors, hand tools, weapon systems, firearm components, and more.

If you have any questions about our capabilities, or if you are ready to discuss your needs, contact us today.