WHO WE SERVE

We specialize in industries that demand extreme precision

Aerospace & Defense

As an AS9100 Certified supplier to the Aerospace & Defense industries, we provide engineering, manufacturing, and secondary machining to support critical component programs large and small. Our clients, which include leading global manufacturers, depend on our expertise in fixturing, stamping and turning to produce a wide variety of parts and assemblies that adhere to DOD, NASA and FAA quality standards. Employing the practices and principles of Lean, JIT, Kanban, and 6 Sigma, our facilities and processes are designed to efficiently and effectively achieve the highest standards of precision.

Capabilities

- Automation

- CNC Milling & Turning

- Engineering

- Laser

- Reverse Engineering

- Stamping

- Swiss Machining

- Tooling

- Wire EDM

Energy

As a supplier to this new and growing industry, we understand and accommodate the demands of constant innovation and changing market dynamics. We match our customers’ needs for a nimble, trustworthy partner by providing quick response times, creative thinking, and reliable R&D and engineering for everything from fuel cells and fuel cell storage to wind, hydro power, and solar. From concept drawings through manufacturing and delivery, we use our experience in precision components and intricate sub assemblies to accelerate production, decrease time to market, and help give our customers a competitive advantage.

Capabilities

- Automation

- CNC Milling & Turning

- Engineering

- Stamping

- Swiss Machining

- Tooling

- Welding

- Wire EDM

Firearms

We supply leading, global firearms manufacturers with components and assemblies that are consistent in quality and reliable in operation. Because of our dedication to both exacting precision and ongoing innovation, our gas tubes are considered by many to be the best in the industry. Lean, JIT, Kanban, and 6 Sigma procedures and principles underlie all our operations and allow our team to support both ongoing and limited run programs with engineering, manufacturing, and secondary machining expertise.

Capabilities

- Automation

- CNC Milling & Turning

- Engineering

- Laser

- Reverse Engineering

- Stamping

- Swiss Machining

- Tooling

- Wire EDM

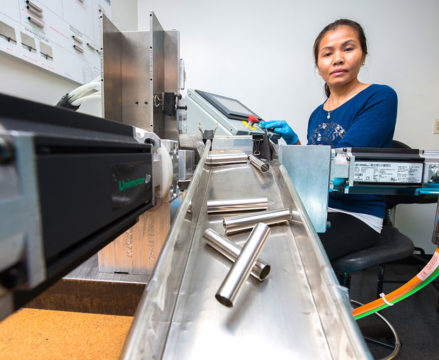

Medical

Our work for the Medical Industry covers a wide variety of parts and assemblies with a specialty in precision tube fabrication for surgical devices. Whether working for a niche manufacturer or a multinational corporation, we apply our Early Supplier Involvement (ESI) project management process to ensure that the highest level of quality and consistency is achieved from first part to last. This system, which fosters open communication channels between CEI teams and customer teams, speeds production by minimizing slowdowns and unforeseen changes. In addition, we are fully aligned with Lean, JIT, Kanban, and 6 Sigma systems to create the efficiencies and predictability necessary to meet the demands and requirements of our medical industry customers.

Capabilities

- Automation

- CNC Milling & Turning

- Engineering

- Laser

- Stamping

- Swiss Machining

- Tooling

- Wire EDM