CNC Milling

- Full 3-axis milling centers (some with 4-axis capabilities)

- Pallet systems for high volume production

- Up to 18 x 36 x 16 inch pieces

CNC Turning

- 2-axis turning centers for smaller components & secondaries

- Puma S240MS 3-axis machining center for more complex machining

- Integrated bar feeding systems for speed

- Support bar stock material of up to 2.5 inches in diameter

- Live tooling option that facilitates off-axis machining operations

- Manufacture components from .0625 inches to 7.0 inches in diameter

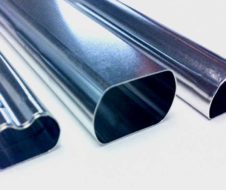

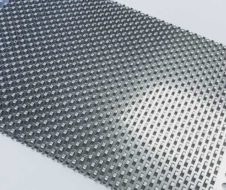

- Up to 300 tons of progressive stamping

- Up to 600 tons of coining pressure

- Able to produce components with thicknesses from .0005″ to .5″

- 300-ton Minster Press; bed size 108″ by 42″

- Over 40 power presses

- Operations: Blanking, Piercing, Forming, Insertion, Drawing, Coining

- Materials: Stainless Steel, Brass, Phosphor Bronze, Nickel, Titanium, Aluminum, Cold Rolled Steel, Precious Metals

- Tsugami B0326-II

- Tsugami B0125A-II

- Tsugami SS20 Super Swissturn

- 5 axis and 6 axis capabilities

- .030 – 1.5 diameter bar stock

- Able to machine stainless, brass, copper, aluminum, CRS

- Manufacture of prototypes, production parts and tooling components

- 4-axis machines capable of wire diameters from .004″ to .012″

- Accuracy to within +/- .0001″ repeatability

- Cuttable travel (XYZ) of 20.5″ x 14.5″ x 12.0″

- Minimum corner radius of .0023″ as necessary

- Maximum material wight up to 2200 pounds

- CDM Drill – hole diameter from .012″ to .250″; 8.0″ maximum work piece height

Example Solutions

We manufacturer a variety of precision metal products, components and assemblies for leading global manufacturers in industries, including Aerospace & Defense, Energy, Firearms, and Medical.